close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-17 Origin: Site

Injection molding masterbatch is a strong mix of additives and pigments. You mix it with raw plastic to change how the plastic acts when making things. Masterbatch helps make plastic products look better, get stronger, or have new features. When you pick masterbatch for injection molding, you get many benefits:

You save money by using mineral fillers instead of some new resin.

You make the plastic stiffer and more stable, so it does not bend.

You make things faster because minerals help parts cool down quickly.

You get the same size products each time and make less waste.

You help the environment by using less new resin.

Injection molding masterbatch makes plastic better by adding color and special features. This helps products look nicer and work better.

Using masterbatch saves money because you use less raw resin. It also helps cut down on waste during production.

Masterbatch keeps color and quality the same in every product. It stops streaks and spots, so things look professional.

You can change masterbatch to fit what you need. You can pick colors and additives for things like UV protection.

Picking the right masterbatch means matching it to your main plastic. You also need to think about what your product needs for the best results.

You use masterbatch to give plastic color or special features. Masterbatch is a strong mix of pigments and additives. People mix these with a carrier resin or wax. This makes it easy to change how plastic looks or works.

Tip: Masterbatch lets you use less resin, add color, and make plastic stronger or better.

Here are the main things masterbatch does:

Lets you use less resin

Adds color to plastic

Makes plastic stronger or protects it from sunlight

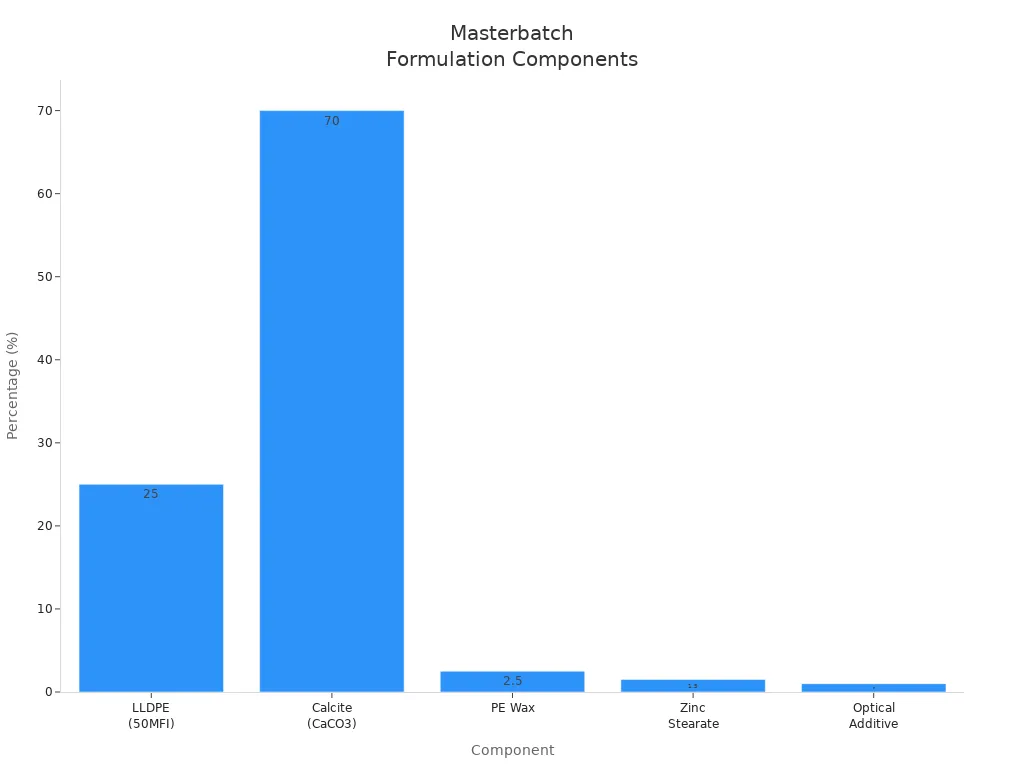

You can see what is in a normal masterbatch for injection molding in this table:

Component | Percentage |

|---|---|

LLDPE (50MFI) | 25% |

Calcite (CaCO3) | 70% |

PE Wax | 2.5% |

Zinc Stearate | 1.5% |

Optical Additive | 1% |

Masterbatch is a strong mix of pigments, additives, or dyes in a carrier resin. The carrier resin is the same as the main plastic you use. You can also add things like UV stabilizers, flame retardants, or impact modifiers to make the plastic work better.

When you use masterbatch in injection molding, your process gets easier and your products get better. Masterbatch pellets mix well with raw plastic. This gives you even color and good quality. You do not get clumps or uneven colors like with raw pigments.

Here are some ways masterbatch helps in injection molding:

Spreads out well, so you get smooth processing and good products

Makes less dust and keeps your workspace cleaner than pigment powders

You spend less time cleaning and fixing machines, so you work faster

You save money over time because you can use the right amount and get the same results every time

You waste less material and make fewer mistakes, which saves time and money

You find injection molding masterbatches in many places. They are used for packaging, car parts, and things people buy. You also see them in food and industrial packaging, wires, cables, farm films, pipes, geosynthetics, and bathroom items. These masterbatches help make products look better, last longer, and stay strong in sunlight.

If you want your injection molding to go well and your products to look and work great, you should use masterbatch.

Color masterbatches help you add bright colors to plastic. These have pigments mixed with a carrier resin. You can pick from many pigments to get the color you want. Some pigments are organic, like phthalocyanine red and blue, and azo red. Others are inorganic, like titanium dioxide and carbon black.

Color masterbatches let you match colors exactly. You can make plastic that is already colored before molding.

Here is a table that shows how color, black, and white masterbatches are different:

Type | Composition | Function |

|---|---|---|

Color Masterbatch | Different pigments with a carrier resin | Adds bright colors to plastic in many uses |

White Masterbatch | Titanium dioxide as the pigment | Makes plastic bright, blocks light, and protects from UV |

Black Masterbatch | Carbon black as the pigment | Gives UV protection, deep color, and holds heat |

Color masterbatches can also change other things about plastic. Some pigments help block UV rays or give a shiny look. You can pick special masterbatches for better performance or cool effects.

Here are some pigments you might use in color masterbatches:

Organic pigments: phthalocyanine red, phthalocyanine blue, macromolecular yellow, permanent violet, azo red

Inorganic pigments: titanium dioxide, carbon black, iron oxide red, iron oxide yellow

Color masterbatches change how your plastic looks and acts. You get bright colors, better UV protection, and stronger plastic. Some pigments make plastic stiffer or help it carry electricity.

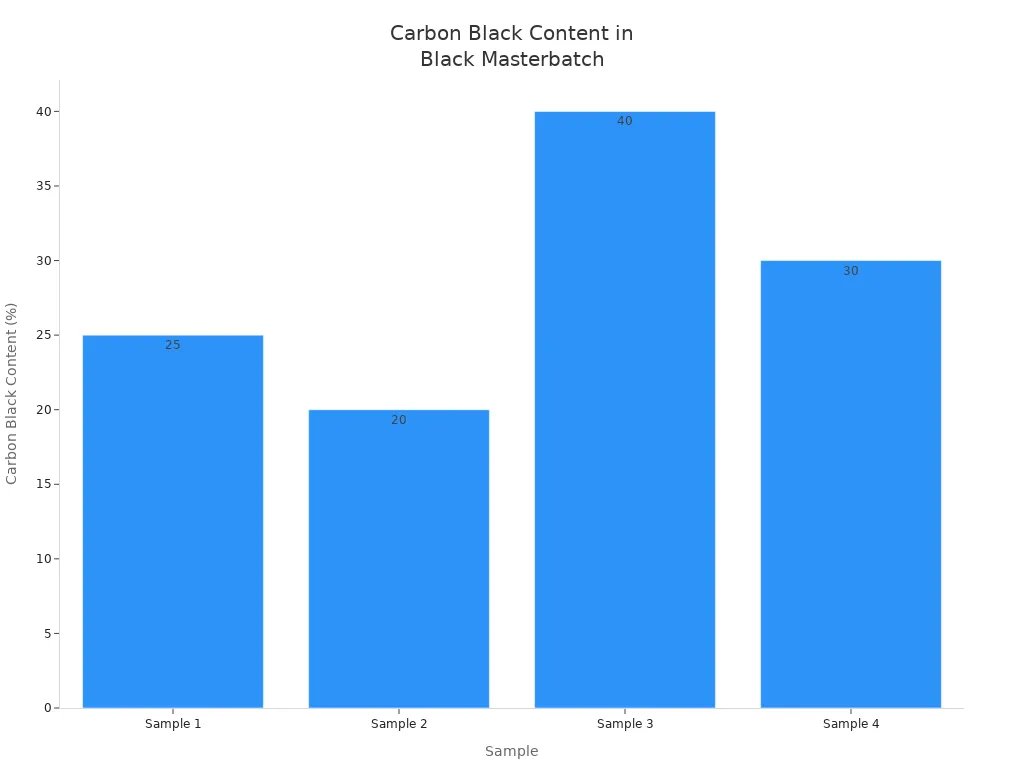

Black masterbatch uses carbon black as its main pigment. You add it to plastic to get a deep black color. It also gives strong UV protection and helps absorb heat. Black masterbatch works well for car parts, packaging, and cables.

Carbon Black Content (%) |

|---|

25 |

20 |

40 |

30 |

You can pick how much carbon black you want. This changes how dark or protective your product is.

White masterbatch has titanium dioxide in it. You use it to make plastic bright and block light. It also helps protect from UV rays. White masterbatch is used for food packaging, medical tools, and home items. You get a clean, strong color that lasts a long time.

Tip: White masterbatch is safe for many uses because titanium dioxide is safe.

Mold release masterbatch helps you take parts out of the mold easily. You add it to your plastic mix before molding. This masterbatch stops sticking and lowers damage. You save time and your products look smooth.

You can mix mold release masterbatch with color or special effect masterbatches. This way, you get easy processing and the look you want.

Using masterbatch can help you spend less money. When you make a lot of parts, the cost for each part goes down. If you make only a few parts, each one costs more because you must change setups more often. The table below shows what can change your costs:

Factor | Impact on Cost |

|---|---|

Manufacturing Process | Needs special machines, which can cost more if they use new technology. |

Batch Size | Small batches cost more for each part because you do not save as much. |

Production Volume | Making many parts lowers the cost for each one because setup costs are shared. |

You also save money because you use less raw resin and make less waste. Masterbatch lets you add color and features without buying lots of different plastics. This makes your work easier and helps you keep your spending under control.

Masterbatch helps your products have the same color every time. The carrier resin in masterbatch is like your main plastic, so the color mixes well. You do not get streaks or spots. This even mixing keeps your product strong and working well.

You get the same color with every batch you make.

You do not have color changes from different materials or machine settings.

You waste less because you make fewer mistakes.

Masterbatch also helps you keep your quality high. You can check each batch for color and fix it if needed. This means you get fewer bad products and more that are just right.

You can pick the masterbatch that fits your needs. You choose the color, the type of resin, and special features like UV protection or antistatic. The table below shows some things you can pick:

Customization Option | Description |

|---|---|

Color | White, black, or any color you want |

Application | For injection molding, blow molding, and more |

Carrier Resin | PE, PP, PS, and others |

Function | UV stabilizers, antistatics, and more |

Special Effects | Pearlescent, metallic, glow-in-the-dark finishes |

You can also pick effects like shiny, metallic, or glow-in-the-dark. For example, pearlescent masterbatch can make your product look shiny like a pearl. This is good for makeup packaging or electronics. Masterbatch can make your plastic stronger, last longer, or even stop germs for special uses.

Tip: Custom masterbatch helps you make products that look cool and work better for your customers.

When you pick a masterbatch for injection molding, you need to think about a few important things. Your choice changes how your plastic looks, works, and lasts. The table below shows what you should think about for each use:

Factor | Description |

|---|---|

Matching to base polymer | You must make sure the masterbatch works well with your main plastic. |

Design principles | Good design, like even wall thickness, helps prevent warping and color changes. |

Process control | Keep temperatures, pressures, and speeds steady for the best results. |

Material handling | Dry materials like Nylon and PET before use to avoid defects. |

End-use requirements | Know what your final product needs, such as strength or heat resistance. |

Always match the masterbatch to your base polymer. Some colorants or additives can change how your plastic acts, especially if it gets hot. If you pick the wrong masterbatch, your product might break more easily or change color. Think about what you want your product to do before you choose.

Tip: Dry your materials well. Wet plastic can cause streaks or weak spots. Clean your machines and use the right Let-Down Ratio to get the color and strength you want.

Here are some easy steps to help you pick the best masterbatch for your needs:

Work with experts: Choose a supplier who knows about color and polymers.

Check product range: Make sure your supplier has many colors and types.

Look for quality: Pick masterbatch that gives strong color and stands up to heat and light.

Think about sustainability: Ask if your supplier uses eco-friendly ways for your end-product application.

Test for migration: Make sure pigments do not move or bleed when you process them.

Pick the right additives: Add UV protection, antistatic, or other features if you need them.

Watch delivery times: Fast and flexible supply helps you keep your work on schedule.

Note: High color consistency makes your products look better and helps you waste less. Machines that run well and dry materials also help you get good results.

Always match your masterbatch to your use and end-product application. This helps you get the best look, strength, and performance from your plastic.

Injection molding masterbatch helps you get better color every time. It makes your products stronger and helps your work go smoothly.

You can make your plastic parts look nicer and brighter.

You save money because you use less material and make less waste.

You pick the best masterbatch by thinking about what you need, what materials you use, and how much you want to spend.

Aspect | Benefit |

|---|---|

Color Consistency | Your products look the same each time |

Cost Efficiency | You spend less and waste less |

Application Fit | You get what you need for each project |

To get the best results, always think about your needs before you choose a masterbatch.

You use masterbatch to add color or special features to plastic. It helps you get the look and performance you want for your products during injection molding.

Masterbatch mixes evenly with your plastic. This gives you the same color every time. You avoid streaks or spots, so your products always look the way you expect.

You can use masterbatch with most plastics. Always check that the carrier resin matches your main plastic. This helps you get the best results.

Think about your product’s needs, the type of plastic, and any special features you want. Ask your supplier for advice if you are not sure.